Winged Sail Vector Diagrams

5.1 Sail and Winged Sail Wind Force Vector Diagrams

We couldn’t resist adding this section. It’s stuff that I did in my aerodynamics classes at University and it will help you really understand sail dynamics. And it’s highly relevant right now because of the America’s Cup AC45 catamarans using winged sails.

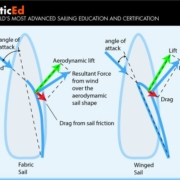

Observe Figure 5.1 below, the diagram on the left shows a traditional fabric sail. There are two forces produced. The first is the drag force due to inefficiencies of the sail and friction etc. Observe that when going in upwind angles you want to reduce the drag force as much as possible because there is no component of the force direction that is helping the boat move forward through the water. The second force is the aerodynamic lift due to the shape of the sail. The two forces can be represented by a resultant force that is acting on the sail.

You can see that reducing the drag is a highly significant factor. With fabric sails in everyday sailing, we can get to the least point of drag by ensuring the sails are never over-trimmed. Over-trimmed sails mean the air molecules are hitting the inside surface of the sail pushing it backward (= drag). Therefore, let the sails out until the point where they just start to backwind at the luff then tighten just enough to remove the back winding. This will be the least point of drag. In the same instance – observe that by reducing the angle of attack, the resultant force moves forward along with the drag force. This again gives you the incentive to let the sail out as much as possible to the point just before it starts to back-wind.

Now let’s take a look at a highly efficient wing shape acting in place of the fabric sail:

The first thing you’ll notice is that the angle of attack is much smaller. This is because of the efficiency of the wing shape and that the wing is not relying on the wind to create its shape. The shape is already predefined.

Next notice that the drag vector is less and because of the lessened angle of attack the direction of drag is not as far aft. Less drag again is due to the efficiency of the wing shape compared to any other shape.

Again because of the reduced angle of attack, the lift vector has swung further forward, and due to the shape efficiency, the force vector has increased in length. This is mostly due to the draft of the shape being moved further forward. IE same as an airplane wing.

Now compare the resultant forces by direction and length. With the winged sail, the resultant force is facing further forward and is larger.

Figure 5.1 – Force Vector Diagram

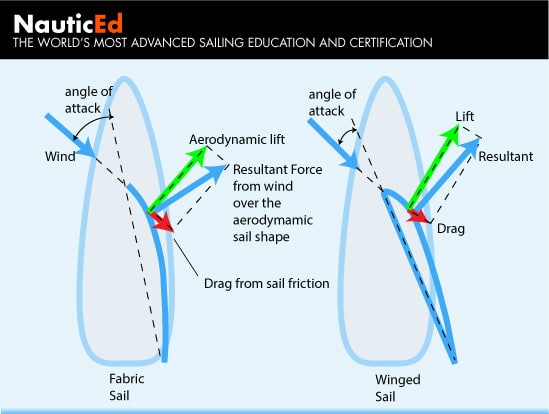

Figure 5.2 shows how we split out this resultant force into a forward driving directional force in the direction of the boat and a heeling force at right angles to the driving force vector. Mathematically we can do this because the vector result of the driving force and the heeling force still equal the resultant force.

Figure 5.2 – Force Vector Diagram Showing Lift and Heel

Notice that with the winged sail, the forward driving force is greater than the fabric sail and that the heeling force is reduced with the winged sail.

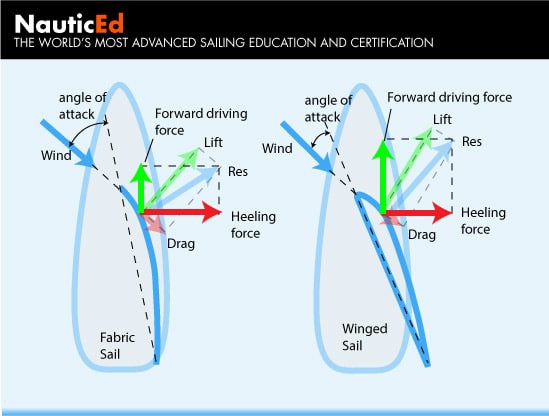

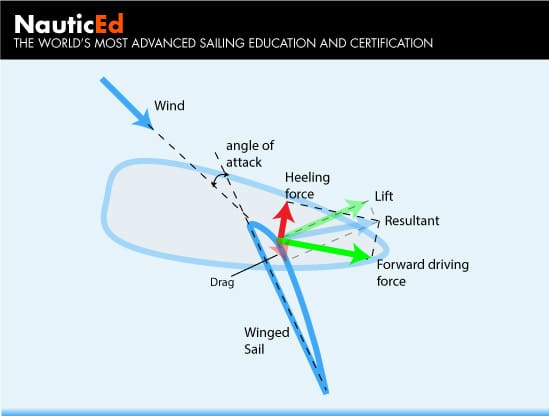

With downwind sailing directions some opposite things happen. The drag has a forward driving component. See Figure 5.3.

Figure 5.3 – Force Vector Diagram Downwind Directions

On the real winged sails, the shape must be symmetrical to allow for the opposite tack. However, the vector math and principles are the same.

With winged sails then, mathematically, there appears to be no downside. Practically we’ve got some issues:

- cost

- For the sail to rotate forward for downwind angles, the wing mast must be free-standing

- On larger boats, the winged sail requires a crane to put the wing up and take it down and…

- …you just can’t leave the sails up overnight in case the winds pick up.

So for now, these winged sails are left to the folks at the high-end race regattas. However, it may be time to recognize the advantages of battened sails since you can now see that shape plays a bigger role than you may have thought. Battens are designed to aid the wind in giving shape to the sail. Thus battened sails are able to have a better angle of attack before luffing and therefore their lift and drag vectors are shifted forward. The drag vector is reduced, helping to reduce heel at the same time. The downside of battens is the loss of convenience when it comes to roller furling systems although boom furling retains the advantage for the mainsail. Vertically aligned battens have been recently introduced in some sail systems to try to gain back some shape advantage.

I recently had the privilege of visiting Core Composites, the factory making these winged sails for the America’s Cup 45 ft Catamarans, the AC45. It was a truly impressive operation. The carbon composite shapes brought back many memories of my Engineering Masters Degree in Composite Materials at the University of Texas at Austin.