Diesel Fuel

The search, discovery, refinement, and resource control of fuel has a rich and very sordid history. But just like a conversation on a boat, let’s not delve into politics.

The Human ImaginationAfter the discovery of liquid fuel, can you imagine then sitting down with a pencil and paper and designing an engine? One with contained explosions in a cylinder pushing down on a rod connected off-centered to a shaft to cause rotation? Would you have foreseen the world change through your mind’s eye? What can you imagine? |

Caution: Never Mix Fuels

Almost invariably, your inboard-mounted engine will run on diesel fuel. Whereas, if you have an outboard engine, it will most likely run on gasoline (petrol). Never ever, as the saying goes, mix drinks—engine drinks that is: gasoline and diesel fuels.

Each type of fuel is produced for use in a specific engine and should never be mixed. If a mixture should happen by mistake, obtain professional help to remove the mixture before running the engine, else your engine will not be running for long.

Filling a fuel tank with the wrong kind of fuel can easily be done if you do not pay attention to what is happening at the fuel dock. A bit of advice: before allowing the fuel dock attendant, or yourself, to fuel your diesel-powered vessel, always ensure—double ensure—that the supply hose is pumping diesel fuel into the diesel fuel tank and not into your vessel’s holding or fresh water tank. This sounds really simple but not paying attention can cost you a lot of money.

Also, note that the names of fuels vary by country. In Europe, diesel is called Gasoil or Gasole. In British-speaking countries, Petrol is the term used for gasoline. It’s important to know your fuels and local names of fuels when visiting other countries.

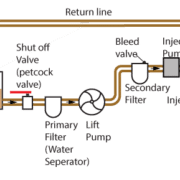

The elements of the diesel fuel system include:

- The fuel fill cap is located somewhere on the outside of the vessel. This is where you fill the tank(s) at a fuel dock or from a can.

- Fuel tanks. Commonly plastic or metal.

- Shutoff valve (aka petcock valve)

- Primary fuel filter (aka water separator)

- Fuel lift pump (aka supply pump)

- Secondary fuel filter

- Injector pump

- Injectors

- Return line

- The diesel fuel itself

Diesel Fuel System

Fuel purity and cleanliness are vital for the proper operation of the engine. Thus make it a habit to check the fuel filters often.

Note that diesel fuel is diesel fuel and nothing should ever be used as a substitute. There is, however, such a thing called biodiesel that can be used if the manufacturer allows it. Fuel for all engines have their own characteristics such as lubricity and energy output. Lubricity affects engine wear. The energy output determines the heat generated in the cylinder; too high energy output can lead to premature burnout of the engine.

Contaminated fuel is the source of 90 percent of diesel engine problems. If possible keep the tank full to help prevent condensation and water from getting into the diesel fuel. If fueling from a dock or barrels that you are not familiar with, special precautions are in order.

When metal fuel tanks are not full, there is the possibility of condensation forming because of temperature variations, and thus there is condensation dripping into the fuel. This may lead to the formation of bacteria and the degradation of the fuel. There are several additives used for retarding this formation, but in general, these are not necessary. Check with local fuel docks for recommendations in your sailing area. Most modern fuels are treated and do not need additives. In addition, tanks are now often made of non-metallic plastic materials that are less likely to create condensation. Check your tank; it will either be stainless steel or plastic.

For safety, there is always a shutoff valve—called a petcock valve—right at the fuel hose leading from the tank. Again, be advised to study your owner’s manual for its location and proper usage.

From the petcock shutoff valve, the diesel fuel flows to a primary or water separator filter that is designed to remove any water. Water in diesel fuel can be very disruptive, from making the engine run poorly to stopping altogether. Whenever your engine sputters or seems to lack power, you should immediately suspect faulty fuel.

Next, a lift pump aids in priming the diesel fuel. It is a small low-pressure pump sending fuel through the secondary filter and onto the high-pressure fuel injector pump.

Diesel fuel exits the injector pump through high-pressure hoses to each of the injectors where it is compressed in the cylinders by the rising pistons. There is also a return line, where unspent diesel is returned to the diesel tank.

Troubleshooting a diesel fuel problem includes checking the water separator filter and ensuring there are no leaks in the system. Spare parts should include filters and an up-lift pump.

Don’t Run Your Engine Dry of Diesel Fuel

Running out of diesel is a big hassle. Since the diesel injector pump needs to create high pressure for the injectors, any air in the line can cause major problems. If there is air in the line, not enough pressure is created and thus no fuel flows to the combustion chamber. In this case, you will need to bleed the line of air. It’s a simple but arduous task. You’ll need to release a value atop of the secondary filter and work a lever up and down attached to the lift pump. Once air bubbles stop exiting the secondary filter, tighten its valve. You may need to further release air from the pipe flowing from the secondary filter to the injector pump. All this requires bending into places you may not be able to bend depending on your age and the last time you did a yoga class.

Consumption

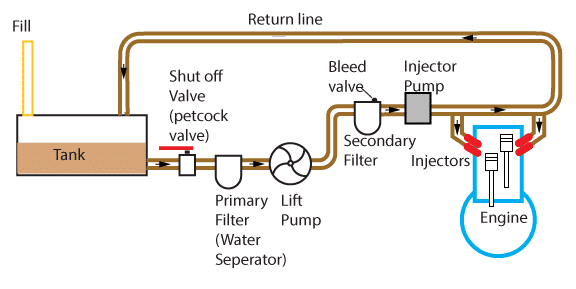

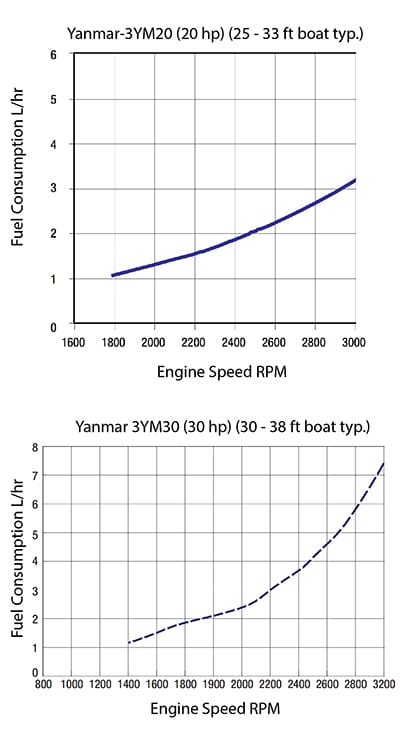

Fuel consumption is a big advantage with diesel engines. Below is a graph of fuel use for some typical engines for typical boat sizes. A typical engine for a 25-33 ft (7.6—10 m) sailboat consumes about 1.9 liters (0.5 US gal) per hour operating at 2400 rpm.

Yanmar Fuel Consumption Specs

Diesel Lubricants

The last fluid we consider is the engine’s lubricant: oil. Just like in an automobile engine, the oil helps prevent heat from developing as a result of piston friction. A diesel oil system consists of the following components:

- Oil—varieties available for various conditions

- Oil filter—for cleanliness

- Dipstick—for measurement

- Oil receptacle—tank

Oil in a diesel engine is under more stress than in a gas engine due to higher pressures and temperatures, and diesel needs a higher viscosity at lower temperatures. Thus make sure you use oil designed for diesel engines when refilling or changing. When checking the oil level with the dipstick, do not be alarmed by blackened oil; this is normal.

If the oil is milky or bubbly, there is a breakdown in the system and either water or fuel is mixed with the oil. Troubleshooting includes checking the level and color of the oil. Maintenance includes recommended scheduled oil changes, often every 100 hours. Spare parts include oil and filters.

Disposal

As sailors, we have an inborn desire to be Earth-friendly. But just in case you’re switching over from a stinkpot (what non-sailors call powerboats) and don’t know any better, disposing of diesel fuel and oil is strictly controlled by law, and violations are punishable. Your vessel must have a placard indicating what is legal and what is not legal. This sign must be displayed next to the engine. Putting it simply, these two fluids must be disposed of in properly designated containers, never in trash receptacles or toilets. Click on the below link for a PDF you can turn into a plaque at your local office supply store.

When you replace your engine oil, simply take it down to the local vehicle oil change garage. By law, they are required to provide oil dump stations for the public and are only too happy to accept your old oil. At home, save a few large plastic bottles around for this purpose. And please make sure you properly recycle the plastic as well. We believe that as sailors, we’ve got a responsibility to lead a green example.

Refueling

Fueling up your boat can be a bit tricky if you’re using 5-gallon (20-liter) containers and carelessness invariably leads to spillage. While you think a few drops here and there is a necessary evil, it is not. Have you ever seen the rainbow film on the water produced by even one drop? It’s not good; and with a whole marina of people doing it, even a few drops can jam up the waterways and make a wasteland of life in the marina and beyond.

Instead, there is a most awesome device called a Super Siphon. It has a one-way check valve so that when you push the tube down into the container, diesel flows into the siphon hose. By vigorously shaking it up and down you fill the hose and siphoning becomes the easiest job ever.

Watch this video.

Siphoning Fuel Easy

You can buy a Simple Siphon from Amazon or many other places.