The Engine – Getting Familiar with a Charter Boat

While this is a sailing boat propelled by the wind and mostly without the need for burning fossil fuels the most devastating breakdown besides hull failure is the engine. Engine failures are categorized into cooling system failure, fuel system failure, electrical system failure, and mechanical failure. Some you can fix at sea and some are best left to others.

It is prudent in this Charter Clinic to discuss in reasonable detail the various systems and how you may affect a fix at sea. Engine failure can complicate the best-laid sailing plans but can be devastating to a charter because of limited time schedules, so we’ll spend some time on the Iron Jenny. The engine can ensure making port in time to grab a mooring ball, maintains battery charge, keeps the beverages cold, and water hot. Diesels will operate smoothly for thousands of hours if maintained properly. They actually demand very little; plenty of clean air, efficient cooling, lubrication, and most of all clean fuel.

Cooling system failure

Oil

Oil keeps the engine lubricated and therefore prevents excess heat from building up from friction. Thus, the oil levels are part of the cooling system and must be monitored closely. Diesel engines also use more oil than automobile petrol engines. Thus when the engine is being used it should be inspected at least daily, or more often if the engine is using oil continually. Keep the oil levels near the fill mark on the dipstick, but under it by just a tad. The low and the full marks are at the bottom of the stick about 1-2 inches apart. Over-filling can cause severe damage to the engine such as blowing out seals and making the engine inoperable.

|

Anecdote |

As part of your daily maintenance, check the oil level and also check the oil pan under the engine for any difference from the previous check.

The Water Cooling System

Heat is also created from the combustion of fuel and so a water cooling system is used to carry away this heat to the ocean.

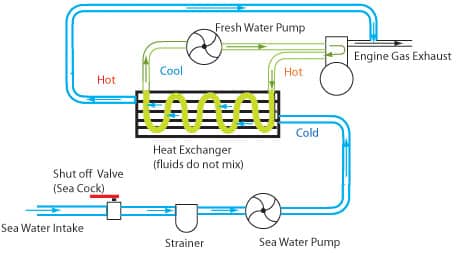

Here’s how the water cooling system works:

- Seawater is drawn through the intake seacock and is piped to a water strainer/filter. In the strainer, possible obstructive materials like seaweed, plastic bags, and sand are captured so as not to clog and do damage to the remainder of the cooling system. Seawater and raw-water terms are used interchangeably since sometimes it might be river or lake water.

- The Sea Water Pump (aka raw-water pump) is a centrifugal pump that is typically powered off a v-belt mounted on the front of the engine as above.

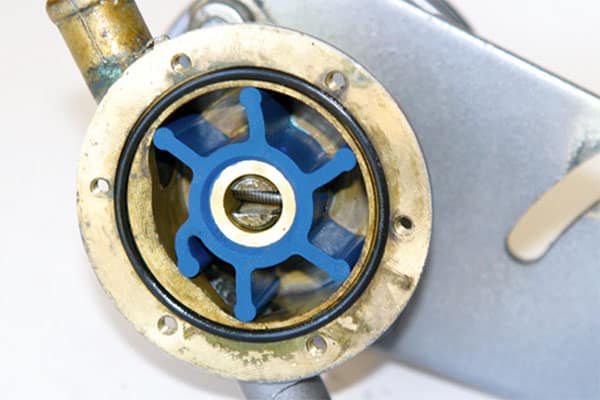

- Inside the Sea Water Pump is an impeller. It is comprised of a rotating central hub with rubber fins that drive seawater (raw water) through the raw-water cooling system.

- Impellers are often at fault in cooling system failure when the rubber fins disintegrate and obstruct outward water flow. The water leaves through a small hole in the exit port of the pump, and shards of the shattered fin can gather in those openings or worse yet, in the openings and throughout the heat exchanger pipes which are even smaller.

A worn impeller pump. Replace ASAP if you see this.

- Water propelled from the pump travels to the heat exchanger. The heat exchanger is a cast iron component that absorbs heat from the engine via the closed water (freshwater) system) and dispels that heat into the seawater system. After traveling through the heat exchanger, the now heated sea water exits through the muffler and out of the boat with the engine exhaust. This comprises the raw water portion of the cooling system.

- The closed (freshwater) cooling system contains a coolant fluid similar to what is in your car radiator. This fluid is circulated by a separate water pump that runs off of a belt in front of the engine. Coolant fluid circulates and absorbs heat throughout the engine. It is delivered to very small pipes also in the heat exchanger in close proximity to the raw water system pipes. Heat transfers from the heated coolant to the cool raw water, which then dispels it overboard.

Overheating

An overheating alarm is a sound nobody welcomes, but it happens all too frequently. It is a very loud high-pitched shrill that goes all the way to your bones.

Whenever an overheating alarm sounds, shut down the engine as fast as practically possible. Preferably immediately. The only reason you should leave it on for a few more seconds is to prevent damage to the boat if you’re in a tight harbor. Seconds in an overheating situation exponentially increase the damage to the engine. Longer time can cause the engine to seize, preventing it from ever starting again. We did say shut it down as fast as possible right?

You can secure the safety of the boat by dropping anchor to prevent it from drifting aground or by setting sail to a safe harbor or bay. Or you can even drift on open seas while you effect repairs. Ensure you designate a watch out for traffic. Only begin to investigate the overheating problem when the boat and crew are safe.

Problems can occur because of low oil levels or in either the closed or raw water systems. A summary of cooling problems and remedies is below:

Closed Cooling System

Caution: Much like a car radiator – do not open the closed water system whilst the engine is hot. Boiling water will spray all over you.

Low coolant levels: Coolant fluid levels should be within an inch of the expansion tank’s cap. Inspect and add coolant or water when the engine is cold.

Water pump belt loose: One belt usually drives the water pump, alternator, and engine. Tensioning the belt is usually accomplished by adjusting the alternator bracket.

Leak in system hoses: If hose(s) leak, observe the engine closely while the engine runs to locate the leak. If possible, replace the hose. If a spare hose is not available, open the expansion tank to reduce pressure and run the engine sparingly until reaching a safe harbor. Usually, there are some hose clamps made available, these may help slow down the leak.

Stuck thermostat: Located on the heat exchanger, the thermostat prevents water entry until the engine has heated to about 185 degrees F. Then it opens to allow water through to begin cooling. If the boat has a thermostat (check the owner’s manual) it will be a cast iron component bolted to the front of the engine block with a large water hose attached. Unscrew the bolts holding it to the block, and carefully pry the thermostat out of the housing; then replace the housing. This will allow raw water to enter the heat exchanger and will control overheating, but remember to replace the thermostat at the earliest opportunity.

Raw Water Cooling System

Obstructed intake. Plastic bags or other materials can be aspirated into the seacock. Close the raw water intake seacock, remove its water hose, and then slowly open the seacock. If water does not flow, remove the obstruction, replace the hose, and start the engine. If water exits through the exhaust port, the problem is solved.

Blocked raw water filter. Close the seacock, and carefully unscrew the filter lid, being careful not to lose the gasket. Remove any debris that could obstruct, replace the gasket and lid, and open the seacock.

Raw water pump. By far the most common overheating problem is within the raw water pump, where the impeller becomes damaged and ineffective. While the water impeller can randomly burn out, the first possible scenario is that the water intake through-hull valve was turned to the closed position by some of your smaller crew mates. If this is the case the impeller will have most definitely burned out since it relies on water to lubricate it. An impeller is a rubber-bladed part that is inside the water pump housing.

Troubleshooting starts with the water intake valve. If it is still open then check the water intake strainer. This is typically a clear plastic housing that has a wire mesh in it to filter out particulate matter from getting to the water pump and exchanger. It may be full of slime, seaweed, or gunk and will need cleaning, if so you’ll need to close the water intake valve first otherwise water will shoot into the boat once you remove the strainer. Once cleaned and reinstalled REOPEN the through-hull intake valve. Otherwise… well that’s obvious.

Secondly, perhaps a plastic bag, seaweed, or something else is blocking the intake of water. If it is practical and safe, then you may want to dive the intake port under the water to ensure it is clear.

If you do find a culprit – keep in mind that you may already have a burned-out impeller anyway and you’ll need to follow the procedure below. Impellers burn out in about 15-20 seconds if there is no water present so chances are NOT good that once you have overheated the engine from lack of raw water supply that your impeller is still intact.

Checking the impeller: Time to get out the tools. This is going to take about 45 minutes and a few skinned knuckles. It’s quite a simple procedure but you should know what you are doing and be a wee bit mechanically minded. However, in many cases, the Charter company may just prefer you to call them or someone from their local list instead.

- Close the through-hull intake valve.

- Locate and remove the water pump. It will be the small pump that is driven by one of the V belts.

- There are screws on the back of the pump.

- Remove these and pull out the old broken impeller.

- Remove all pieces of rubber from the pump

- Remove the hoses leading to the engine heat exchanger and flush them out.

- Remove the housing that connects the water hose to the heat exchanger and clear out any lodged pieces of disintegrated impeller. Reconnect.

- Insert the new impeller (if available), reassemble, and reinstall the water pump.

- Set the V belt tension so that there is about 1 inch of stretch at the midpoint between the two drive pulleys.

- OPEN THE THROUGH HULL INTAKE VALVE.

- Leave the engine cowling open and do not start for 1 hour as cold water instantly against a hot engine can cause the engine head to crack.

- Once the engine is restarted ensure that water is ejecting out the back of the boat through the exhaust.

Another great resource for more info on replacing a water pump impeller is at http://www.boatus.com/boattech/casey/09.htm and here is a great blog of someone replacing an impeller as well. http://boatwizard.blogspot.com/2007/09/how-to-change-water-pump-impeller.html

Stalling

Almost invariably you’re going to get a line wrapped around the prop and it’s almost always from the dinghy. In fact we challenge you to make it through a week-long charter without wrapping the dinghy painter line around your prop. If you find that your engine starts but stalls when you put it in gear – you can bet that there is a line wrapped around the prop. Fortunately, most charter sailing vacations are in places where the water is warm. You’re going to need to dive under with a knife and clear the line off the prop. Make sure the gear lever is in neutral and you have removed the keys from the ignition before you venture overboard. For this reason, we always have a mask on our own personal boat.

| Anecdote One time (not at band camp) one of our crew came paddling up in a dinghy at about midnight. They had been out for hours. The dinghy motor had stalled miles away and they could not get it to engage into gear without it constantly stalling. When they paddled up with their woes – I simply announced that they had a line caught around their prop. The frustrated look on their faces was pretty funny (to me). However, I only knew this because the exact same thing happened to me years before. LOL. |