Searching for a leak in the boat

Over the past few months, we’ve had excessive water in our Beneteau 373. If you don’t know, water is supposed to be on the outside of the boat. Only Rum and a few other libations are supposed to be on the inside.

So, yesterday we got fed up and launched a search and plug campaign. This meant thinking of every possible scenario of why water might be in the boat. So here is a list of things to check. Look for discolored water streaks next to any suspect area. If need be, sprinkle talcum powder next to the seacock and observe over time if a trail of water is left.

We had some discussions about the sheer volume of water in the boat (still under the floor boards) so we knew the culprit had to be big. A few days before when we checked the boat there had been a big rainstorm so hmmm we thought that might be something. But after a thought, we realized that to get approx 50 gallons of water of water into the boat from a rain storm would not be a little crack somewhere.

General integrity inspection: – We walked the entire boat looking for any cracks and culprits. We found a crack inside the anchor locker. We plugged the exit hole and hosed about 20 gallons of water into the anchor locker. Over the next hour or so the water level had not moved. Nope – not that one.

Seacocks: – These are through hull valve fittings whereby drain hoses plug into. There are a lot. Many are above the outside water level but also many below: Galley seacock, handbasin seacock, air conditioning cooling water inlet, shower drain, toilet maserator, toilet water inlet, refrigerator drain, raw water cooling inlet for engine. Seacocks usually have a handle to turn to close the valve. Don’t discount above the water line seacocks. Once on another boat we kept getting water into the boat but only while under sail. Turned out that the drain hose from the basin to an above water line seacock had fallen off. When the boat heeled to port the seacock was under water. Our inspection revealed every seacock to be dry and clean. Moving on.

Bilge pump exit: – This is usually above the water line but you should inspect the fittings and connections all the way back, since the exit will be below the water when healing which could suck water back in. There is a check valve (one way valve) in the line to stop water flowing backwards, check that. Checked! Nope.

Packing gland, stuffing box: – The propeller shaft exits out of the boat through the stuffing box. This is below the waterline and is thus often a source of water leaks. A packing gland is inside the stuffing box to create the seal but since the shaft turns it is difficult. Some boats have an “active gland”. This has a turning screw inside the stuffing box to move water towards the seal and create back pressure. If your boat has this, you will see next to the stuffing box an inlet seacock and a tube from it to the stuffing boat. All are sources of leaks. Our active stuffing box proved dry as.

Sail Drive: – This is an alternate shaft drive system used mostly in Europe. The shaft in encased in a housing that exits the boat vertically though the hull. Gears change the direction of the drive to horizontal where the propeller attaches. The sail drive unit is a potential source of leaks.

Toe rail: – All along the tow rail, there must be a seal to prevent water getting into the boat. Inspect this. For obvious damage or gaps. The toe rail covers and protects the seal between the molded hull and the molded top of the cabin. You can test for leaks by closing all hatches and shutting off all egresses. Then use a shop vac on reverse blow to pressurize the inside of the boat. You’ll have to tape up pretty good the area where you stuffed in the shop vac hose. Now soap down the hull of the boat and look for bubbles. We did not get around to this since we knew the leak was bigger than a tiny crack.

Side stay deck connections and chain plates: – Once on my friend’s boat, the mast came down under sail because he forgot to check the deck seal where the sidestays (shrouds) go through the deck and chain plate to the bulkhead below. The entire bulk head rotted out over time because of constant water getting into the boat. Checked! Ours – fine.

Water Heater: – The water heater fills from the water tanks. If the water heater is allowed to freeze it will blow out a safety stop then anytime you turn on the water supply pressure you are pumping fresh water tank water into the boat. Checked! All good.

Water tanks: – Many boats have a plastic water tank whereby the inlet and exit from the tank are on top. This prevents water leaks out the bottom – but … maybe your tank is not like this. Our water tanks were in good shape and all holes are in the top.

Hatches: – Close hatches and get out the hose. All good here.

Rudder: – The boat is usually designed with a hollow rudder post that is molded into the boat and the post rises above the water line (clever). Thus, unless this is all cracked from hitting the bottom its unusual to see a leak here. But check it anyway. Use the talcum powder if suspicious. No tell tale signs on ours.

Keel: – The keel is bolted through the hull to the top of serious stringers molded into the hull and there is a seal between the keel and hull to prevent water coming in. The bolts are highly tensioned. This technology has been essentially perfected over the years but … older boats, poor quality manufacturing, or groundings can affect the integrity of this seal. There are lots of articles on the net on how to fix a leaking keel. With out pulling the boat, ours looked fine.

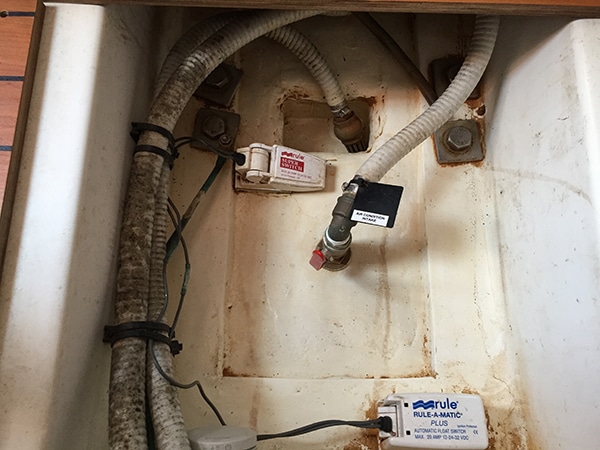

Air conditioner: – Ah ha – the culprit (we think). So … a few months back the air conditioner was playing up a little so we took a look. The raw cooling water strainer was full of junk (we cleaned that) and the pan that collects the condensate was pretty rusty with a collection of condensate water in it. And there was rusty water in the bilge which meant the rusty pan had been spilling water over and out of the pan. So we had our local AC boat guy do two things (1) Add freon and (2) install a venturi vacuum hose with a one-way check valve into the cooling water line to keep the pan dry. Unfortunately, we surmise, he forgot to properly tighten the clamps around the cooling water line. AND SO – every time the AC was running it was pumping water into the boat. That was only part of the mystery because after we fixed that (before the rain storm) somehow the bilge was still full after we tightened the clamps and pumped the bilge dry. Hmmmm – so what we figured out was that water was still in between the hull and the subfloor and while the rain storm did not add water to the boat the 40 knot wind rocked the boat around enough to allow water to slush around enough to come out of the weep holes into the bilge. We tested the hypothesis by rocking the boat ourselves. Sure enough, during the rocking, water came out from under the subfloor and flowed into the bilge. We stuck the shop vac up into the weeps holes and right now we have the heater set on 85 deg F to dry out the boat with a hatch cracked open to let the steam out.

(Update – checked the bilge again today – it is dry – yay – whew!)

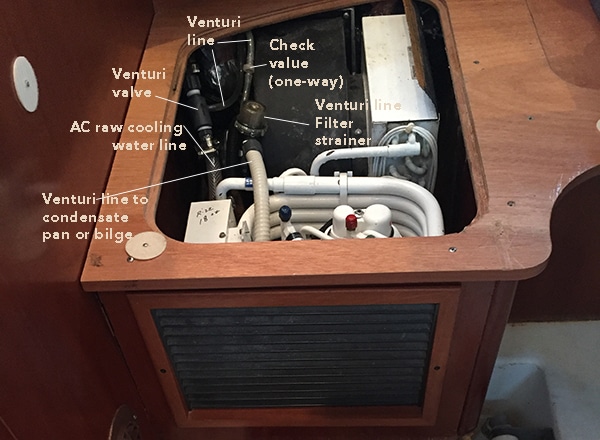

What is very interesting is how effective the venturi is on the air conditioning cooling line. Using a venturi is a way to create a vacuum when water is flowing. So what we are considering is to vent the condensate pan directly to the bilge always and run the venture line down into the bilge. This way the venturi takes care of not only the condensate but other water in the boat any time the AC is running. This is Texas and so even if we are not at the boat we run the dehumidifier selection on the AC. We have a strainer/filter in the venturi line so that it does not clog up the cooling water line and the venturi valve it placed in the line close to the exit out of the boat.

Here is a pic of the venturi line stubbed onto the AC cooling line:

Venturi Valve inserted into the AC cooling water line creates vacuum to empty the condensate pan

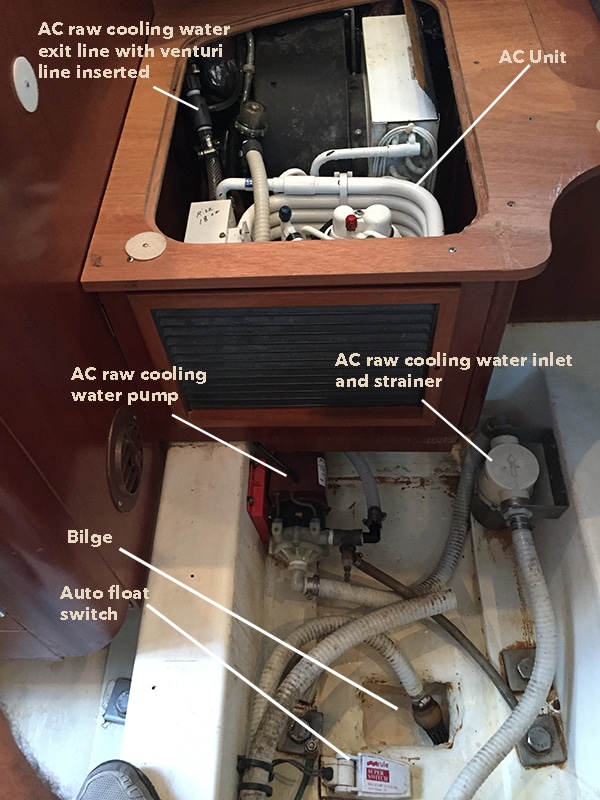

And here is a pic of the AC with bilge and the AC raw cooling water line and the AC system. From this you can see how we can run the venturi line down into the bilge.

AC and AC raw cooling water system

Hint – don’t forget to clean your AC raw cooling water strainer.

If you liked this post, consider taking our NauticEd Skipper Course. Our education goes a step above. The course is also now available in paper book format from Amazon. See this page for a listing of our sailing books.

Update – Two Weeks Later:

Dry as an old bone :)

Dry bilge