Hello down there

Climbing the mast for repairs

Every now and then you’ve got to do it. Or at least some body does and while I’m still limber enough I was the one elected to go up.

The issue was the during the commissioning process on our Beneteau 373, it looks like the set screws holding the extrusions together were not screwed in with with loctite. Loctite is a liquid that cures and prevents screws from backing out over time – a sailor’s best friend.

So the sailing lesson today is to use loctite on screws on your boat where you don’t want to lose them or when you don’t want to climb the mast.

This issue ended up being fairly serious. The whole problem started with the Texas sun which completely degrades the UV Dacron sewn onto on the leech of the sail to protect the sail itself from sun damage. After 2 years the UV Dacron was just falling off and so the sail needed to be taken in for repairs. It should have been pretty simple.

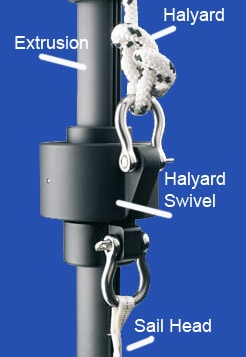

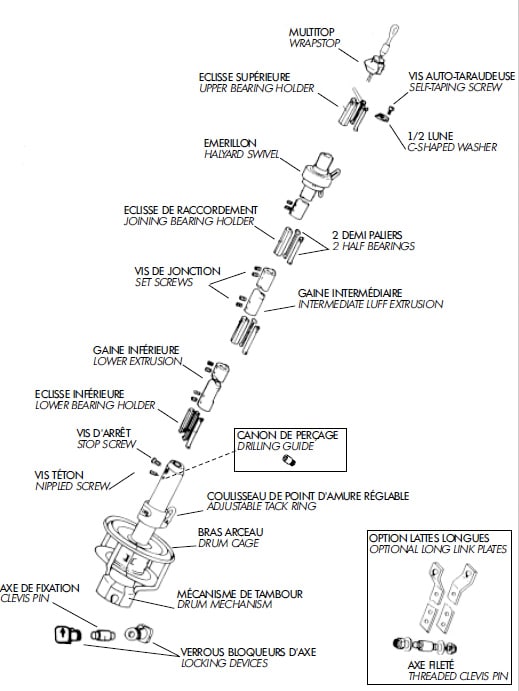

We have a Profurl roller furling system on our Beneteau 373 which we are very happy with and so dropping the sail is pretty easy. Just unfurl and let down the halyard swivel via the jib halyard. What happened was that a set screw in the extrusion near the top of the furling forestay had backed out and jammed the halyard swivel on its way down. This caused a sudden jolt on the sail as it was descending and broke the bolt rope at the luff of the sail. Admittedly we should have controlled the speed a bit more when lowering the sail.

The Halyard Swivel

Now the Halyard swivel was stuck. Funny enough – the first person we asked for a bosons chair said no but they had a rock climbing harness. Apparently this person was a mountain rescue guide and always caries his harness with him – go figure!!

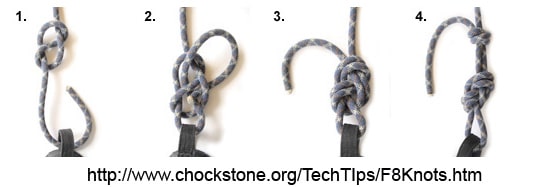

Figure 8 Rock Climbing Knot

We used a spare halyard as the main hoist and and the spinnaker halyard as the safety back up. I tied the lines on to the rock climbing harness using a figure 8 rock climbing knot. Then we also used a boom topping lift to pull necessary extra tools up and down. When ever going up the mast make sure you have a big pouch of some sort to put tools in so that you won’t drop them.

The next 30 minutes was spent trying to unjam the halyard swivel from the set screw which had backed out of the extrusion. Once this was done we had to loosen the other set screws to pull the extrusions back together. The Whole assembly is made up of 10ft long extruded aluminum pieces which are set screwed together by an extrusion joiner.

It’s a good and simple design to assemble – just make sure that the set screws are put in with Loctite. The manufacturers specs even say to do this.

But I must say we had a wonderful day out sailing on Lake Travis prior.

Here is a video of the Profurl system.